Build Video

To the FliteTest Community,

MESArc is back to share the great projects researched, designed, created, and evaluated by our students. The articles won't be created every week as in past years, however, we will make sure to notify you guys of any new plans that come out of the think tank in articles in the future.

As an exemplar of the upcoming FT STEM program, we wanted to present an article to you in a format that our students work through in the development of their projects called the FT Design Brief.

Hope you enjoy Tylers MF-Slim Racing Quad.

FREE PLANS

Purchase Build Kit: http://www.altitudehobbies.com/aircraft/mesa-rc-foam-fighters-kits

Research

Identify and justify the need for a solution to the problem.

Problem: Create a quadcopter using no hardware and taking less then 10 minutes to construct.

Justify: A quick way for beginners to get into multirotors without having to spend class periods constructing the frame.

Present 2 or more Existing/Similar solutions to this problem.

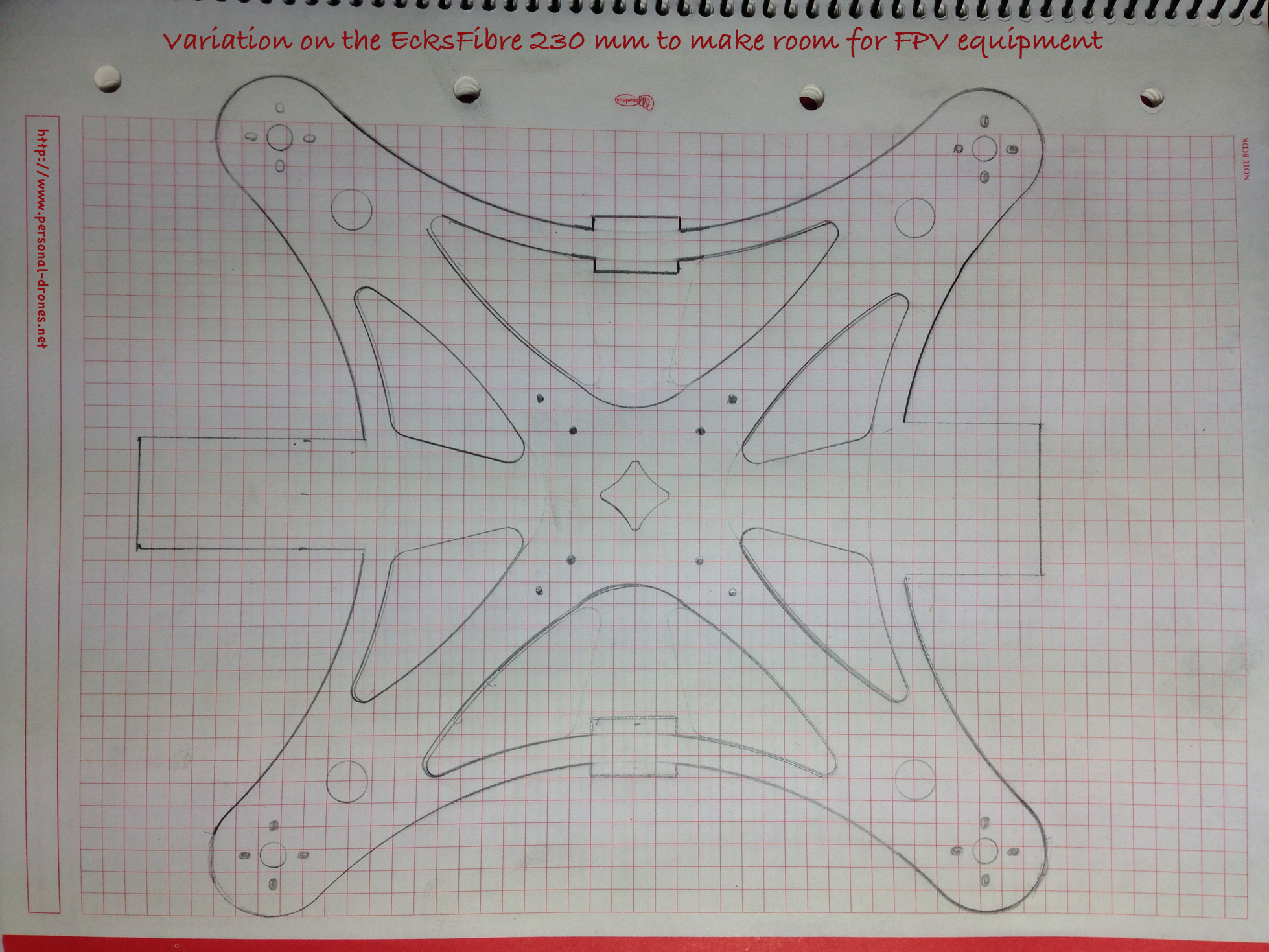

Solution 2: http://www.personal-drones.net/wp-content/uploads/2014/04/variation-on-ecksfibre-2-personal-drones.net_.jpg

Show Research that supports your understanding of related content in correlation with the solution.

Research

- Quadcopter: An aircraft using four motors for pitch, yaw, and roll maneuverability.

- Best and cheapest materials to be used: "Gator Board" Using this material would make for a light, durable, and cheap framing solution.

- Dense polystyrene foam core has solid wood-fiber veneer for added strength.

- Paintable, direct digital print, direct screenprint surface.

- Strongest foam board available.

- Cut to size with a knife, saw or router.

- Electronics and their rough sizes: FT Power Pack E (https://store.flitetest.com/power-pack-e-racing-mini-quadcopter/)

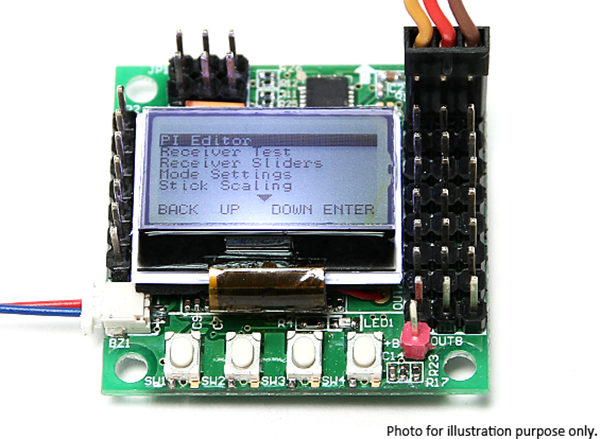

- Control Board and dimensions: Mini KK Board: http://www.altitudehobbies.com/flight-controller/kk-mini-multi-rotor-flight-control-board-36x36mm

- FPV Gear and dimensions: http://www.fatshark.com/product/1759.html

- Looking under motor layout, I found this setup will work, using the following image to remember which motor is which.

- Initial connection for board; Motor one first slot on top right, then two, three, and four. Make sure lightest color signal wire is on the farthest left pin, that is the signal line. Mini KK Board should have the signals labeled on the left to then be hooked up to the receiver.

- Canopy ideas:

http://cdn.shopify.com/s/files/1/0275/9387/products/canopyPack03_1024x1024.jpg?v=1407216560

http://cdn.shopify.com/s/files/1/0275/9387/products/canopyAction04_1024x1024.jpg?v=1407216559

Design

State or Develop the Design Specifications below.

Design Specs:

- Must be a quadcopter

- Mini size in scale for appropriate electronics

- No hardware

- Quick to make frame

- light weight

- durable

- Anyone can build it without prior experience

Develop 2 or more possible thumbnail solutions.

Thumbnail 1

Thumbnail 2

Generate your final solution.

Final Solution:

Based on the generated solution, develop a design plan that organizes the creation approach.

Design plan:

- First laser cut design using Foam Board as a reference.

- Approving Foam Board prototype, laser cut gator board

- Laser cut motor mounts

- Glue components together

- Install electronics

- Bench test quad

- Test quads performance

Log In to reply

Log In to reply

Log In to reply

Log In to reply

I have re-drawn it in Sketchup.. and extended the main body front and rear by 50mm.. perhaps rather too big but better that than too small, its easy to cut it down later...

I will make up a canopy when the frame is made..

Log In to reply

The costing of a depron build works out at $1.5 /model

Log In to reply

Keep flying

Log In to reply